13 Tips to consider before buying or selling Wood Veneers.

- August 03, 2019

- by

- Team Natural Veneers by Turakhia

In woodworking, veneer refers to thin slices of wood and sometimes bark, usually thinner than 3 mm, that typically are glued onto core panels to produce flat panels such as doors, tops, and panels for cabinets, parquet floors and parts of furniture. They are also used in marquetry.

Tips to consider before buying Wood Veneers:

- Always prefer minimum 0.5mm veneer thickness as it gives a better finish and life to furniture.

- Always look for a minimum 100% hardwood grade base plywood for veneers. It gives strength to furniture.

- Always keep veneer sheets in pair of two, with the front side facing each other to avoid scratches on veneer surface.

- Always sell wood veneer sheets in ascending or descending group sequence as veneer natural grain structure would be varying.

- Make sure that wet veneer sheets should be air-dried before placing it in racks. It eliminates chances of fungal attack in air and veneer sheet delamination.

- Put limited water on veneers having a high character like knotty, burls, annual rings and crotches as it has a high tendency to retain water and delaminate.

- Maintain room temperature environment in veneer warehouse to avoid any warpage or cracks in veneer sheets.

- Do not cut veneer from the front side to avoid the problem of chipping of the natural veneers.

- Make sure to use a sharp blade and the correct degree while cutting veneer sheets to avoid the problem of chipping.

- Always finish veneers with good quality sealer and topcoats to get the best finish in veneers.

- Do not sand rough-cut veneers at the time of finishing.

- Always buy veneers from the quality-conscious brand like Natural Veneers by Turakhia.

- Do not waste the smallest piece of wood and veneers. Try to use it.

Need more info?

Visit our website: www.naturalveneers.com

Call us: +91-9136460666

Email:

[email protected]

Share this post: on Twitter on Facebook

You may also Like

Obliged To Have Such A Wonderful Response At Acetech – Mumbai 2019

November 29, 2019

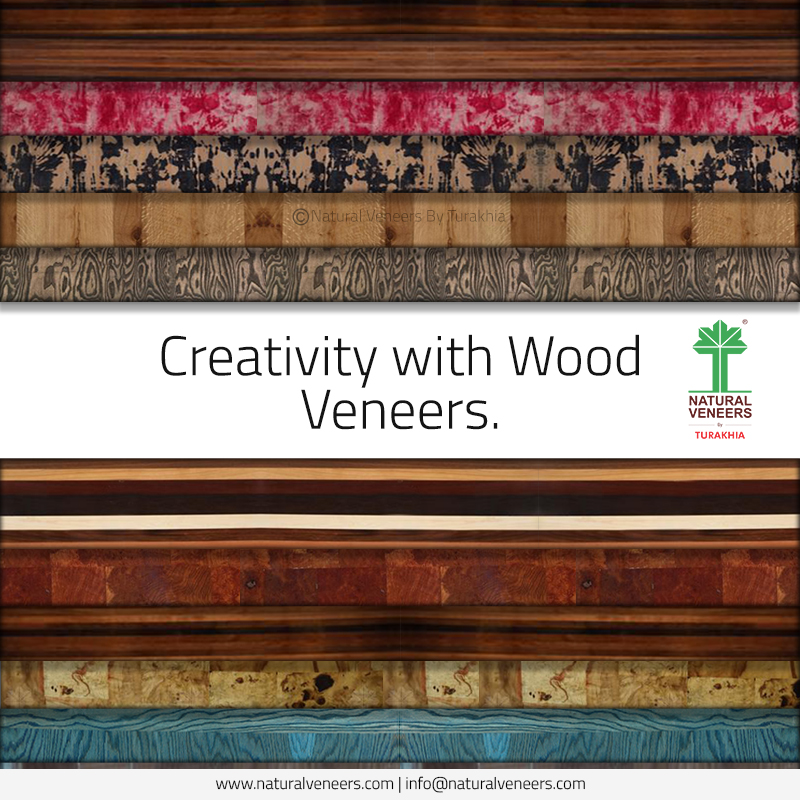

Creativity with Wood Veneers

September 11, 2019

What is Wood Veneer and How to Refinish it?

July 05, 2019