Natural Veneers Factory Tour Video – Step-by-Step Veneer Manufacturing Process

- April 19, 2010

- by

- Team Natural Veneers by Turakhia

Natural Veneers Factory Tour Video. Veneers Manufacturing Process. Plywood Manufacturing Process.

Introduction: Discover the Art of Veneer Manufacturing

Step into the fascinating world of surface innovation with Natural Veneers’ exclusive Factory Tour Video. Experience a behind-the-scenes look at the meticulous process that transforms raw timber into decorative veneers, setting new benchmarks in quality, precision, and sustainability. Whether an architect, designer, or wood enthusiast, this detailed tour will enrich understanding of the veneer manufacturing process and why Natural Veneers by Turakhia stands out as an industry leader.

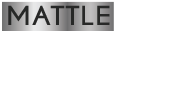

Step-by-Step Veneer Manufacturing Process

Log Selection and Preparation

The journey of every high-quality veneer begins in the log yard. Expert professionals at Natural Veneers hand-select timber based on strict quality benchmarks, looking for desirable grain patterns, species, and overall log health. Once selected, logs are kept in optimal humidity conditions—often sprayed with water or soaked—to prevent cracking and preserve their natural moisture.

Debarking and Softening

After selection, the logs undergo a careful debarking process to remove all bark and contaminants without damaging the underlying wood. To achieve smooth, defect-free slicing, logs are then softened through controlled steaming or soaking at temperatures between 80°C and 100°C for up to 72 hours. This step ensures uniformity and enhances the wood’s pliability for the next phase.

Slicing and Cutting

The core of veneer manufacturing lies in slicing logs into thin sheets. Using advanced rotary or slicing mills, softened logs are transformed into ultra-thin, uniform wood veneers. Techniques like rotary, flat, quarter, and rift slicing are employed to deliver a wide range of grain patterns and finishes, maximizing the natural beauty of each species.

Drying and Quality Inspection

Freshly sliced veneers are immediately routed to specialized drying units, where they are air-dried or jet-dried to bring the moisture content down to an optimal range (typically 6–10%). Strict quality control protocols are followed at every stage—each sheet is inspected for uniform thickness, absence of defects, and consistent color, ensuring only the finest veneers reach customers.

Clipping, Splicing, and Packaging

Following drying and inspection, veneers are clipped to standardized sizes, with edges trimmed for perfect fit. For larger surfaces, sheets are expertly spliced and joined—sometimes in book match or slip match patterns—to create flawless, expansive panels. The finalized veneers are then labeled, measured, and carefully packaged in protective materials, ready for safe transport across the globe.

Why Choose Natural Veneers by Turakhia?

Natural Veneers by Turakhia combines craftsmanship, cutting-edge technology, and sustainable practices to produce world-class decorative surfaces. With full process transparency and a passion for wood, the brand has become synonymous with quality and innovation, appealing to designers and luxury furniture makers worldwide.

Watch the Factory Tour Video

Explore this immersive video journey to see every step in action—from log selection, through sophisticated cutting, to the final finishing touches that make Natural Veneers unique. Witness first-hand the rigorous standards and attention to detail that define the brand’s reputation and product excellence. Contact us today to learn more about veneer applications, schedule a personal factory visit, or explore Natural Veneers’ premium collections. Share this blog with fellow enthusiasts, and let us know your thoughts and questions in the comments below.